Aviation Industry Case Folding Machine

We designed a machine that folded a very complicated case for the aviation industry, the product was unique, using a laminated card the blank needed to be partially folded into shape and then a precise line of hot melt needed to be applied to two sides simultaneously before the final folds that made the complete box.

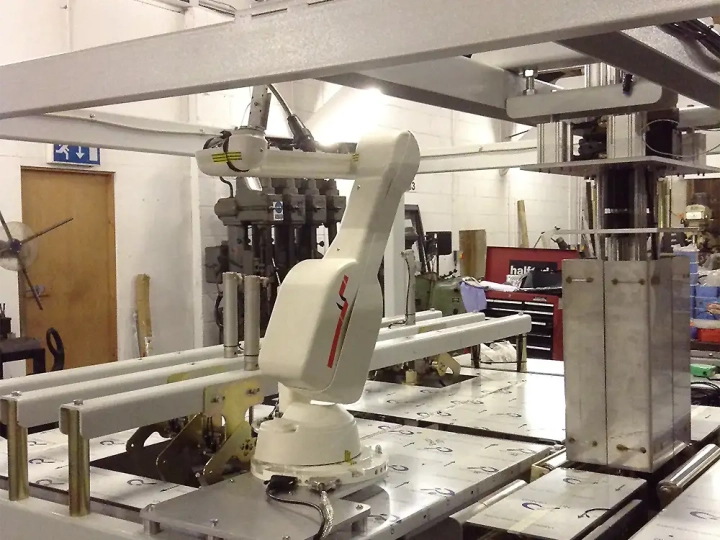

We used two small robotic arms with hot melt glue guns to apply the glue over almost two linear meters each side and with a specially developed glue that was able to remain liquid throughout the folding. The result was a large case that was water tight and to a specific size tolerance. The machine was controlled with an Allen Bradley plc that interfaced with the robots to harmonize the folding with the application of the glue.

Custom Pallet Dispenser Design

We designed and manufactured a pallet dispenser for a customer who was unable to find a standard machine and we were asked to produce one to suit their layout.

The standard pallets arrive on site in a stack twelve high, the stack is loaded vertically in the machine and then with a simple control and some very robust arms and pneumatics we lift the stack off the bottom pallet which is then able to be driven out onto the conveyor track for loading, the process repeats as pallets are required.

This machine releases the fork lift driver considerably, previously having to lift the top pallet off the stack and placing on the conveyor every time to now simply loading a stack as required.

Starwheel Applications and Prototype Development

Starwheels are a simple means to orientate a product, usually incorporated in a line from a cartoner they are used to turn a product over from maybe laying on a wide face to standing on their narrow edge. Depending on the product and the final requirements a starwheel can “flip” 250 cartons per minute in a simple form or count and collate the product as it enters another process. The wheel can be simply free rotating or driven precisely with stepper motors to fulfil the requirements.

We like prototypes, its interesting to take a concept from a customer and demonstrate that it can evolve into a working process, many of our bespoke projects have started as a sketch to be proven with a prototype test rig and then to a full machine design, it may be a mechanical device or a control system to establish if the idea will work.