Comprehensive Control Systems and Components

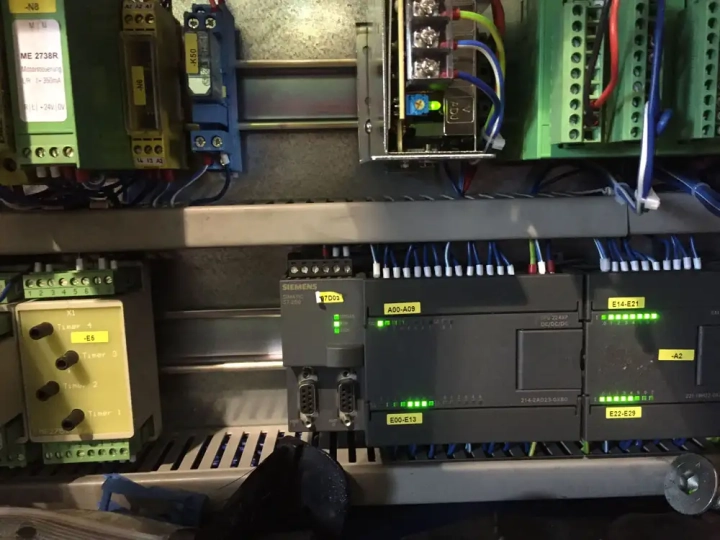

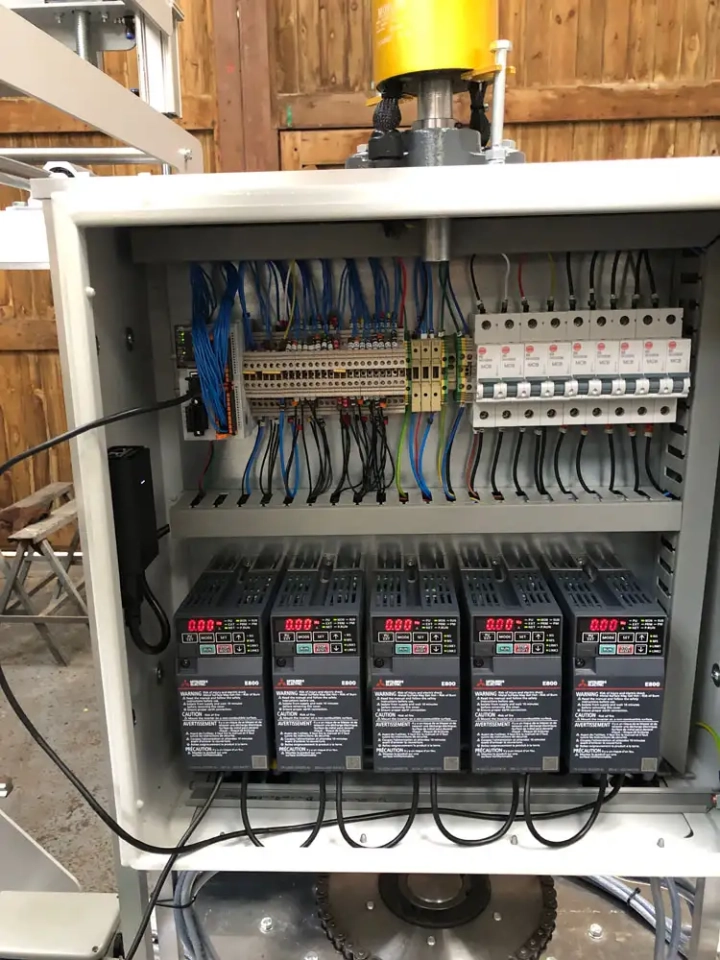

All machines need controls, from a simple conveyor to a multi drive machine we build all our own panels and write all our own software. We use the major makes of controls, Allen Bradley, Siemens, Mitsubishi to name but a few, we also retain some of the older systems such as Omron so chances are we can talk to some of the oldest systems.

Inverters for motor controls can range from simple stand alone units to multiple systems controlled directly from the PLC via ethernet coms. HMI units allow for easy controls as well as fault finding screens such as guard door displays and tuning screens for adjustments to timers, counters and motor speeds. Stepper motors are now an economic means to enhance machine control, previously standalone systems were required to control stepper motors, now with the correct hardware they can be directly controlled from a simple PLC with all the features required.

Modernising Legacy Equipment and Safety Standards

As machines age an area of concern is always the controls, safety standards have changed as well so an option is to upgrade the control system and give a good machine a make over and update for the next ten years or more.

Guarding standards now require a much higher level of safety with dual circuit and monitoring devices becoming standard, modern invertors with built in safety features can often mean that a machine can be reset much faster than originally possible.

Panel Building, Fault Diagnosis and System Adaptation

We can build panels to your requirements and drawings, we can fault find on panels usually without the original drawings, we have reverse engineered a few systems where the original builders are no longer available. There is almost always a way round a problem be it with non-availability of an original part or a required change to the control.